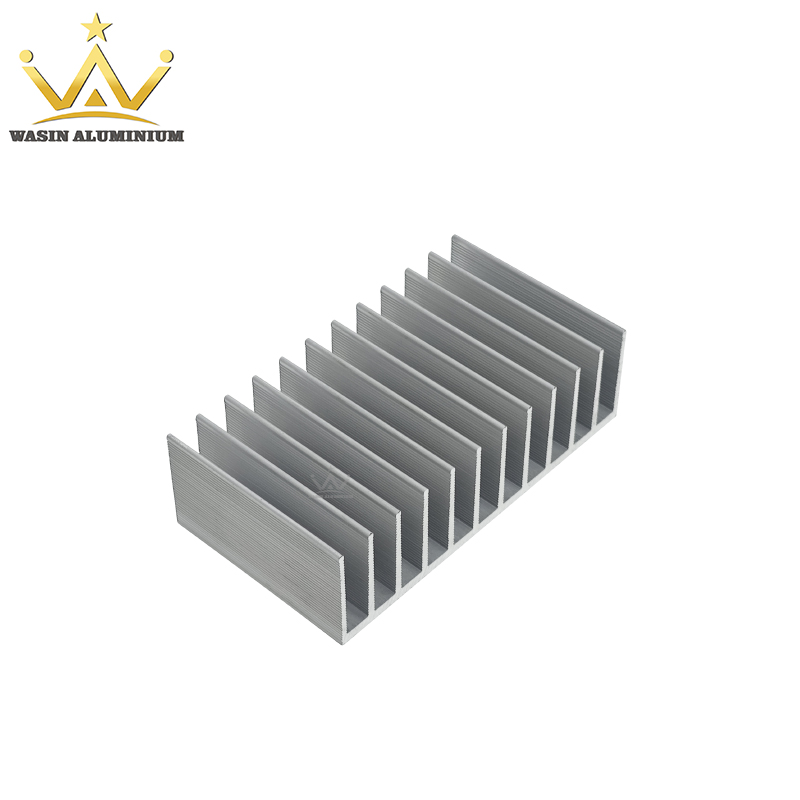

| Aluminium alloy | 6063、6005、6060、6061、6165、6082、6351、 6013、5083、7005、7075 |

| Temper | T4、T5、T6 |

| Thickness | Mostly from 1.0 ~ 2.0 mm,Min at 0.5 mm; Max at 10 mm or according to drawing design |

| Length | 500 mm < L < 9000 mm |

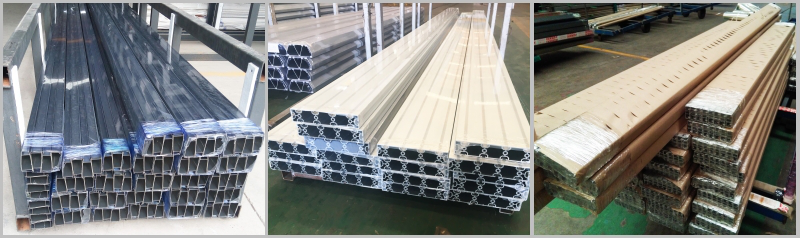

| Surface treatment & color | a) Anodized & electrophoresis: silver、champagne、golden、bronze、brown、black |

| b) Matt electro-deposition: golden、grey、silver、black | |

| c)Powder coated: white、blue、yellow、brown or customized |

|

| d) Wood transfer: oak、wilow、teak、yellow pear、walnut or customized |

|

| e) PVDF double or triple coating: white、grey、brown、black or customized | |

| f) Polish & brush: silver、champagne、bronze、golden |

|

| Profile extrude size: | Max width: 400 mm; Max diameter: 290 mm |

| Factory capacity: | Monthly output about 4000 tons; Max monthly capacity about 6000 tons. |

| Production standard | GB5237-2008 |

| Lead time | Mould making 7 days; Mill finish 10 days; Powder coat 15 days; Anodize & electrophoresis 18 days; other surface about 20 days. |

| Dimensional deviations info(6063-T5) | Angle deviation:±1.0° |

| Plane clearance: less than 0.37mm | |

| Bending degree: less than 0.3mmfrom 300mm | |

| Twist degree: less than 1.7mm from 1m profile | |

| Cutting angle: less than 2° | |

| Mechanical characteristic (6063-T5) | Vickers hardness (HV)≥58 |

| Webster hardness (HW)≥8 | |

| Tensile strength: no less than 160 N/mm² | |

| Anodizing characteristic | Average thickness of anodize film: no less than 10 μm |

| Partial thickness of anodize film: no less than 8 μm | |

| Anodize sealing quality: no less than 30 mg/dm² | |

| Hardness (Pential scratch testing): ≥ 3H | |

| CASS test (24h):≥ 9 grade | |

| Alkali resistance(24h):no less than 9 grade | |

| Wear resistance(sand drop testing): ≥300 g/μm | |

| Powder coating characteristic | Coating indentation hardness: ≥ 80 |

| Coating thickness: 60 ~ 120 μm | |

| Smallest local thickness: > 40 μm | |

| adhension (dry、wet、boiling water): 0 grade | |

| Wear resistance(sand drop testing): ≥0.8 L/μm | |

| Hydrochloric Acid resistance: no blistering and obvious change | |

| Solvent resistance: ≥ 3 grade | |

| Detergent resistance: no blistering, no loss of film adhension and obvious change | |

| Mortar resistance: no loss of film adhension and no visual change in appearance | |

| Boiling water resistance: no air bubble、 wrinkle、cracks、falls off and color change on test specimen |