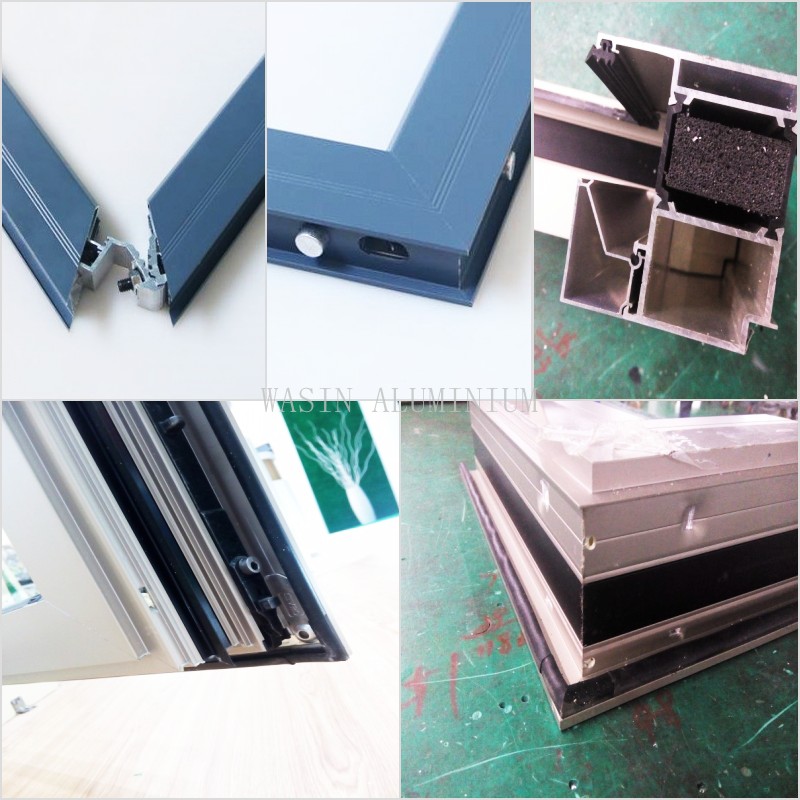

In addition to the special customization of industrial aluminum profiles, the aluminum profiles after deep processing are also very special. There are many aluminum profile factories in China. Most aluminum profiles have complete specifications, such as 20, 30, 40, and even 90, 100, and 120 series from stock. However, there are very few manufacturers that can do deep processing, and there are very few manufacturers that can do a high degree of deep processing. The processing of aluminum profiles includes the processing of aluminum profiles themselves and the processing of aluminum profile frame products.

The processing of aluminum profile mainly includes cutting, punching, tapping and surface treatment. In addition to these basic processing techniques and methods, the processing of aluminum profile frame products also requires customized cutting, punching, tapping and surface treatment according to the design drawings. For example, cutting length, punching position, hole size, tapping size, surface does not need to be customized, etc.

If we want to increase the processing of aluminum profiles to a new level, which is different from other manufacturers in the market and more competitive, what should we do?

The so-called new height of aluminum profile processing actually means that the quality of processed products is better than other products, the processing method is more efficient than other methods, and the processing cost is lower than the market. Cost is something that any entrepreneur must pay attention to and strive to reduce. If the processing cost is low, the price competitiveness of your products in the market will decrease. The investment in processing seems not small, such as more than a dozen production lines, 30 high-quality imported CNC control centers, multiple double-head CNC precision cutting equipment, etc., which undoubtedly increase the cost. However, due to these advanced and sophisticated equipment, the production and processing costs are greatly reduced, time costs are reduced, and losses are reduced. All these add up to reduce the total cost.