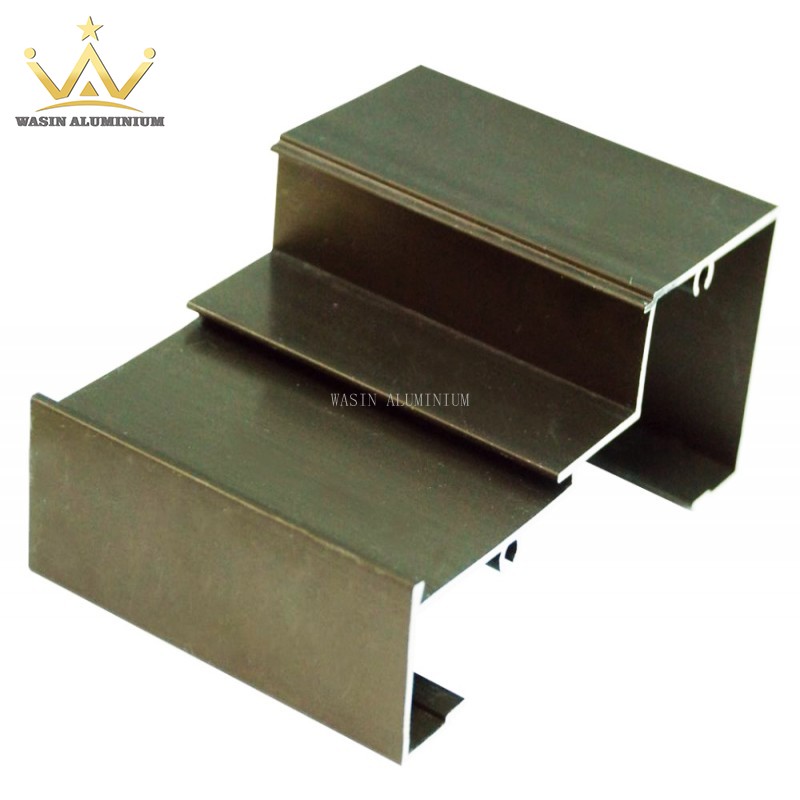

Aluminum alloy door and window curtain wall is a new type of building exterior wall form since the development of the aluminum alloy industry. In this building form, new technology, new materials and new structures are applied, and it is one of the most used exterior wall structures in large buildings.

Basic methods for installing aluminum alloy doors and windows

The profiles aluminum for windows and doors are installed horizontally and vertically into the opening, and the gap between the outer frame and the wall should be filled according to the design requirements. During installation, mineral wool strips or glass wool felt strips should be used for layering and rubbing, and a gap with a depth of 5mm to 8mm should be left on the surface of the gap for filling the sealing material. At present, the installation of aluminum alloy doors and windows mostly adopts the back plugging process, that is, after the bricks or the concrete of the wall door and window openings are filled, the windows and doors are inserted into the openings.

Most of the connecting parts are galvanized iron sheet. The connecting part and the window frame are connected by self-tapping screws and cored aluminum rivets. The connecting part and the wall are connected by shooting nails, plastic expansion bolts, metal expansion anchor bolts, etc.

The sealing technology is divided into two types: flexible T technology and rigid technology. The flexible process is layered filling of lightweight materials such as mineral wool or glass wool felt strips, leaving a 5mm-8mm deep slot at the edge, sealed with injection sealant. The rigid process is embedded with 1: 2 cement mortar, and the mortar is in contact with the frame. The surface is fully coated with anti-corrosion layer to prevent the cement from corroding the aluminum frame and shorten the service life.

The window sill finishing material must reach into the bottom sill of the aluminum frame with a circular arc of R≥100Inrn to avoid submerged diving and hidden danger of seepage. Finally, clean the dirt, rust and other sundries and install doors and windows.

Installation quality inspection of aluminum alloy doors and windows

The installation of profiles aluminum for windows and doors must be assembled according to the design drawings, and should be done after the indoor and outdoor walls are painted. The frame and the opening wall should maintain a reasonable gap. When the wall of the hole is a common cement mortar powder surface, the gap is 20mm ~ 25Inm; when the wall of the hole is decorated with brick or mosaic, the gap is 25mm ~ 30mm, and the sealing gap is 5mm ~ 8mm.

After the frame, the verticality, flatness, horizontality, and diagonalness should be checked, and then the wooden wedges should be temporarily fixed. Wooden wedges are placed at the four corners to prevent improper force and deformation and dislocation. The combo box should be assembled first, and then installed through the long-distance spelling material, segmented spelling material, and basic. The reinforced material should be rust-proofed, and the connection parts should be galvanized screws.

The method of fixing aluminum alloy door and window frames should be determined on a case-by-case basis. The walls of the cave are of a concrete structure and are fastened by a nailing process; the walls of the opening are of a masonry structure, which can be fastened by expansion screws with impact drills. The fastener of the connecting frame is not less than 50mm from the edge of the wall, and it should avoid the wall gap to prevent the fastening failure. Cleaning after sealing should be performed with a soft cloth moistened with water, and should not be wiped with metal tools.

The main problems in the installation of aluminum alloy doors and windows

(1) The dimensions of the door and window openings are not allowed

During the construction of the abundant body structure, due to the inaccuracy of the reserved openings or the consideration of the decorative surface at the end of the reservation, the reserved openings appear to be too large, too small, and offset. Not only brings difficulties to installation, but also affects the quality of the facade.

(2) Aluminum alloy doors and windows are loose and cannot be fixed firmly

The main original diaphragm of aluminum alloy doors and windows is loose because there are not enough connections or small pairs. The connection distance between aluminum alloy doors and windows should be less than 600mm, and the length from the frame corner should not be more than 180mm. Blind and brutal construction, one-sided pursuit of reducing costs, a 1.2m-high window with only two connectors, will cause doors and windows to loosen. At the same time, the connection piece is too small, which is one of the reasons for the looseness of the doors and windows.

After the aluminum alloy door and window connectors are fixed, the gap between the frame and the wall is unfilled, and the pavilion is not filled at all. Partial displacement causes the entire frame to loosen, and also brings the hidden danger of water seepage from the frame.

(3) Finished product protection for aluminum doors and windows

Aluminium desk doors and windows are high-grade doors and windows products, in addition to having functions of doors and windows, they also have a certain decorative effect. There is a layer of protective oxide film on the surface, which should be strictly protected during construction, and must not touch or scratch the surface, otherwise it will affect the look and feel and use function.The installation of doors and windows can be done by erection of the door frame and corner protection of the lintel. The anchor alloy should be properly protected, and the protective tape or film must not be removed at will.

It is strictly forbidden to hang on aluminum alloy doors and windows and place heavy objects. Once the aluminum alloy doors and windows are contaminated, they should be cleaned immediately with a soft cloth, oil and water, and the areas with severely stained surfaces should be painted.

Tag: Aluminum hinge for casement door ; 7 shape handle for aluminium window ; Aluminum sliding door roller ; Friction stay for aluminium casement window